February - March 2017

February - March 2017

80

81

boatingonthehudson.com

Find Us On Facebook at Boating On The Hudson

Dave Weakley is the owner of

American Boat Restoration

and has been helping

Northeastern boaters keep their boats in fine trim and good repair for over 40 years.

Dr. Gel

by Dave Weakley

Ask

2006 • Over a Decade with Dr. Gel • 2017

“Email me or call me with your questions! I’ll be happy to help you out”

americanboatrestoration.com /

email:

boatrepair@aol.com/

Office:

413.665.7424 /

Cell:

518.577.7799

From a professional repairer’s point of view and for ease

of repair the best color boat to buy would be one that is

white. One reason is white reflects the heat from the sun

far better than any other high pigmented color. There is

less fade, it’s easier to match and has fewer pigments in

it. In southern states, e.g. Florida you will see the majority

of boats docked are white. Darker colors especially dark

navy blues, dark reds and greens absorb more heat. In

addition the more complicated the color schemes the

more challenging and longer it takes to repair thus

increasing the repair cost. In the past we have removed

darker colored gelcoat samples off older boats to have

a computer match done to mix gelcoat and even a

computer sometimes cannot get a perfect match. It may

match one spot on the boat but not in another area. A

good color match also depends greatly on how well the

boat has been cared for and how much sun exposure it

has had. During my repair process I always color restore

the repair area(s) by compounding and if needed wet

sand to get the original color back as best as possible.

Often the entire sides of the boat are done. This helps to

insure the new gelcoat will blend with the original and

“With the coming of spring, I am calm again”

Gustav Mahler

“I should buy a boat!”

If that’s what you’re thinking there are important

things to consider when choosing the color boat you

want whether it is new or pre-owned. I have advised

many people over the years on this subject and feel

it’s important to bring up again as we look to another

boating season!

WHITE VS. blue-red-yelow-orange-green-black-grey

What’s the best choice?

My answer is white. My boat is white…

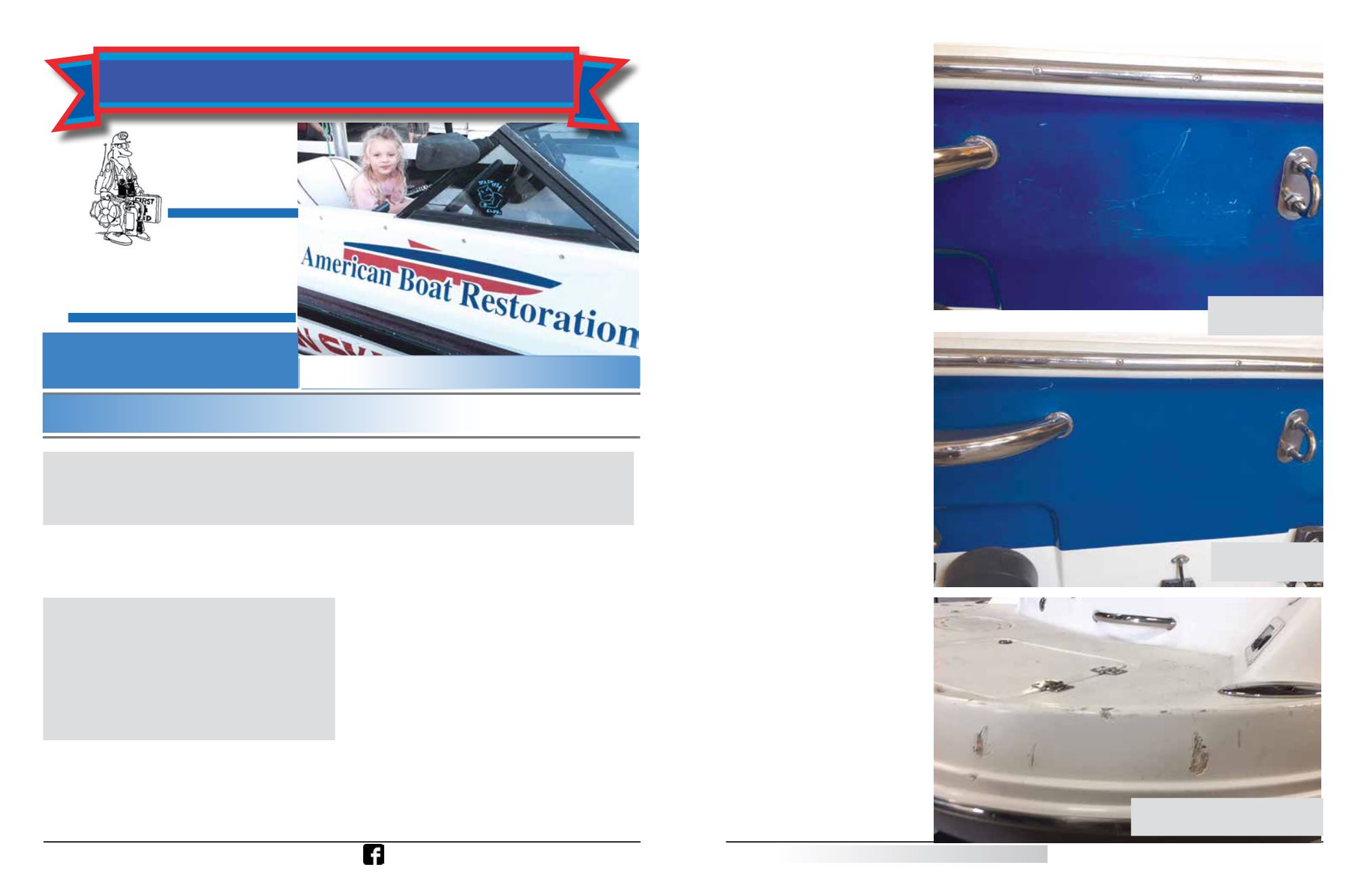

Color restoration

complete.

Chalked with light

scratches.

Unfortunate storm damage on

well kept 2007 Chaparral.

helps to achieve a good color match

and avoid blotches.

The most common material boats

are built with is polyester resin. The

material is inexpensive and lighter in

weight than epoxy resin. Polyesters

never stop curing and get brittle with

age. The more exposure to the sun a

boat gets themore brittle and bleached

it becomes.

All gelcoat is porous; It needs regular

maintenance. I’ve written this many

times. You can clearly see boats on the

water that are well maintained and

those that are neglected. The suns UV

rays will penetrate the porous gelcoat

quickly. The damage from sunrays

can be slowed down by periodically

applying a gelcoat sealer glaze followed

by a good marine UV protecting wax.

The best way to protect gelcoat is to

keep it covered. Consider full canvas,

roofed boat lifts, indoor storage, etc.

Your investment is expensive protect it

as best as possible.

In the spring when boats are prepped

for summer use the owners uncover

them and they are washed down; some

use soaps such as Dawn liquid dish

washing detergent. While it’s good

for grease and dishes, it’s not a good

choice to clean porous gelcoat. It strips

the wax and the sealer glaze making

the gelcoat vulnerable to UV light

penetration and fade. The best cleaner

to use to wash your gelcoat is a good

boat soap made especially for boats.

There are situations when a harsh

cleaner is needed such as “On-Off” an

acid cleaner that removes waterline

stains, algae, rust and gas stains. This

type of cleaner will definitely remove

the protecting sealer glaze and wax.

The hull will be susceptible to water

seepage and osmotic blistering.

There are two ways to help eliminate

this problem. The first is to apply Epoxy

barrier on the hull starting at the

waterline down. Epoxy barrier paint is

as close to impervious of a paint you

can apply to protect the hull fromwater

intrusion as you are going to get. You

can also acid wash the epoxy barriered

hull and not worry about any damage

that may occur. An alternative way to