June 2017

82

Find Us On Facebook at Boating On The Hudson

The first thing I do when there are

transom decay concerns I look across

the outside and inside of the transom

and look for indentations where

anything is thru bolted. When the

transom was new it was really solid and

bolts were tightened. In a soft transom

the bolts have indented themselves into

the transom. Next I use the handle end

of a screw driver and do the ole’ tap test

on the entire transom. I am looking for

a nice crisp solid ring tone indicating

solidness. If there is a thud sound it

means moisture and softness is present.

I continued to examine other parts of

the boat. I check stringers and engine

mounts. First I check to see if the engine

mount bolts are tight. If they spin, it’s

likely there is moisture and softness

present. The screw driver tap test can be

done along the stringers also. Stringers

can be built out of many different

materials e.g. wood/foam/composite.

The tap test will give an idea of what the

condition of the stringer is but the best

indicator would be to use a moisture

meter.

How is the transom repaired?

In the case of the Sea Ray, the first

step was to remove the engine, all the

hardware, hydraulic pumps, wires, trim

tabs, hydraulic lines, speedo lines, depth

finder, fish finder, etc.etc.

The bilge was cleaned, scrubbed, and

degreased. Every bit of oil removed.

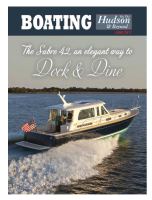

Inside the transom the fiberglass “skin”

was strategically, carefully and surgically

removed using special equipment.

This cut out “skin” was used to make a

cardboard template. The rotted core material was removed using chisels, pry bars, flat

bars, hammer, vacuum, electric chain saw. I used whatever tool it took to clean out the

water soaked core material.

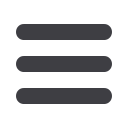

Next I ground out the area and sanded it flat. I used the cardboard template to cut

sheets of ¾” and ½”marine plywood. These were laminated together using vinyl ester

resin and fiberglass cloth. I had to achieve a thickness of 2-1/4” for the new transom.

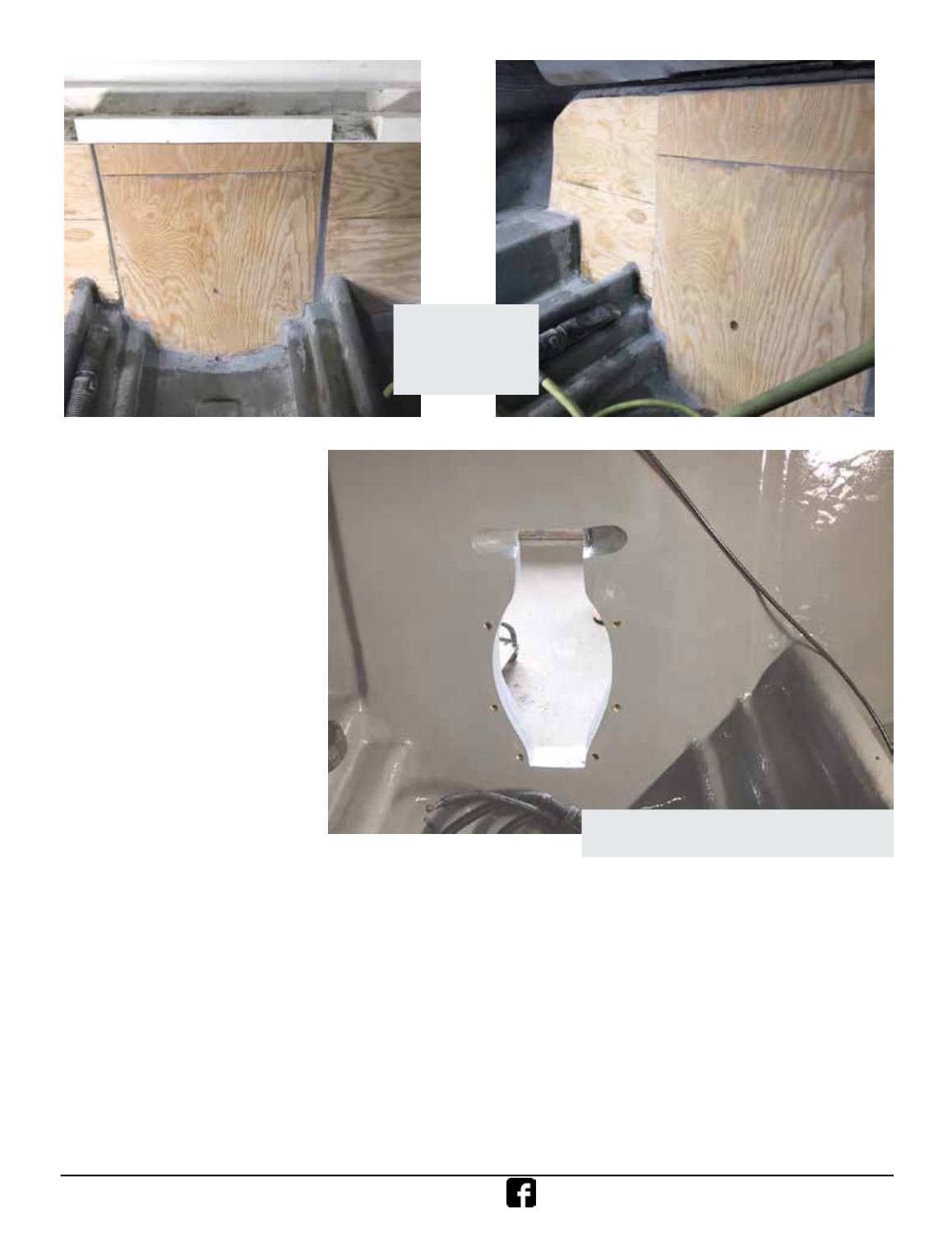

This piece was inserted and secured. All the original holes including the large hole

for the outdrive were recut. The entire project was painted with bilge paint to finish.

Know what you are buying! The structural backbone of the boat is the stringers and

transom along with cross members. It needs to be solid and kept in good soundness

just like the foundation of your house needs to be strong. The boat may look beautiful

and sleek, run well but can have major hidden problems. If it needs floor, stringer and

or transom repairs it will be costly!

Have the boat inspected by someone who knows what they are looking at before

you make an expensive purchase.

New third and last

layer of plywood.

Ready for final

fiberglass covering.

Hole for intermediate housing hole cut out

and new bilge paint. Ready for assembly.